There are several printing processes that can be used to print on bottles. Here are some of the most common ones along with their characteristics, advantages, and disadvantages.

Screen Printing: Screen printing is a versatile and commonly used method for printing on bottles. In this process, ink is forced through a mesh screen onto the surface of the bottle. The ink is then cured to make it permanent. Screen printing is known for its durability and can produce high-quality images. However, it is time-consuming and expensive for smaller print runs.

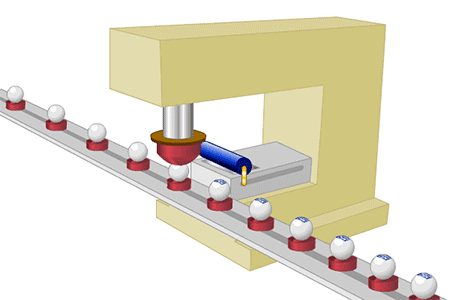

Pad Printing: Pad printing is a popular method for printing on irregularly shaped objects such as bottles. In this process, ink is transferred from a plate to a silicone pad which then presses the ink onto the surface of the bottle. Pad printing is quick and efficient and can produce high-quality prints. However, it is not as durable as screen printing and can fade over time.

Digital Printing: Digital printing is a newer method that uses digital technology to print images directly onto the surface of the bottle. This method is quick and efficient, with no setup required. It is also ideal for printing small quantities and multiple designs. However, the print quality can be lower than other methods and it may not be as durable.

Heat Transfer Printing: Heat transfer printing involves printing an image onto a special transfer paper which is then applied to the surface of the bottle using heat and pressure. This method can produce high-quality images and is ideal for small quantities and multiple designs. However, it is not as durable as screen printing and can peel or crack over time.

Label Printing: Label printing involves printing the image onto a label which is then applied to the surface of the bottle. This method is quick and efficient and can produce high-quality images. It is also ideal for printing multiple designs. However, the label can peel or wrinkle over time.

UV printing technology has become more mature and is now a popular printing method for various applications, including printing on bottles. UV printing has the advantage of curing the ink instantly with UV light, which can result in higher-quality prints and faster production speeds compared to traditional printing methods. UV printing is also more environmentally friendly since it does not require solvents. Adding UV printing to screen printing can indeed result in better quality and more durable prints on bottles.

In terms of recommendations, it really depends on your specific needs and budget. Screen printing is the most durable and produces high-quality prints, but it can be expensive for smaller quantities. Digital printing is a good option for smaller quantities and multiple designs, but it may not be as durable. Pad printing and heat transfer printing are both good options for irregularly shaped bottles and smaller quantities, but they may not be as durable as screen printing. Label printing is a good option for multiple designs, but the labels can peel or wrinkle over time. It’s best to speak with a printing professional to determine which method is best for your specific needs.

Water transfer printing and glue printing are less common methods of printing on bottles compared to the methods I mentioned earlier. Here are some brief explanations of these methods along with their characteristics, advantages, and disadvantages.

Water Transfer Printing: Water transfer printing, also known as hydrographic printing, involves transferring a design onto the surface of the bottle by dipping it in water. The design is printed on a special film which is then transferred onto the bottle using a water-soluble adhesive. This method can produce high-quality images and is ideal for irregularly shaped bottles. However, it is a complex and time-consuming process, and it may not be as durable as other printing methods.

Glue Printing: Glue printing involves printing an image onto a special glue, which is then applied to the surface of the bottle. The glue is then cured using UV light to make it permanent. This method can produce high-quality images and is ideal for printing on irregularly shaped bottles. It is mostly used in aluminum-plastic tubes and all-plastic tubes.

In general, the methods I mentioned earlier (screen printing, pad printing, digital printing, heat transfer printing, label printing, and UV printing) are more commonly used for printing on bottles. Water transfer printing and glue printing are less common and may not be as widely available. As with any printing method, it’s important to consider your specific needs and budget when choosing a printing process for your bottles. If you don’t know which printing is more suitable, please feel free to contact Somewang(send email to [email protected]), we will provide you with the best choice!

We are Somewang Packaging, We Make Packaging Easy!

Welcome to subscribe us to get more packaging information!