PCR Packaging

500ml PET Bulb Shape Bottle with Pump for Personal Care Shampoo Products

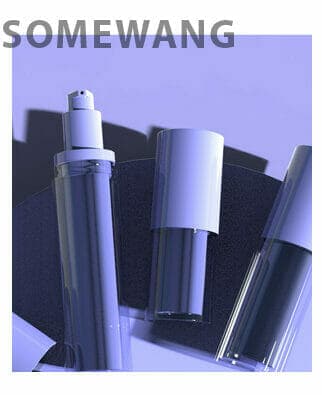

Round Output Mouth Airless Luxury Serum Bottle 30ml ~ 150ml

30ml~150ml Airless Plastic Serum Bottle

Customized HDPE 200ML Lotion Bottle with Soft Touch Material and 100% PCR

CATEGORY

SWPKG Catalogue Download

NEWSLETTER

Keep up with the latest news, special offers and other discount information. Enter your e-mail and subscribe to our newsletter.