Electromagnetic induction sealing is a non-contact gasket sealing method in the heating process. It can be used to seal and preserve the contents of various non-metallic containers.Good air tightness, leakproof and strengthen the protection of health and safety.

Principle: the use of machine to generate electromagnetic field, when the metal material induction electromagnetic field to generate eddy current magnetic field, resulting in metal material instantaneous temperature up to achieve the practical purpose of magneto-thermal conversion.

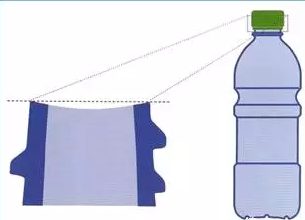

Electromagnetic induction sealing gasket sealing way based on the above principle, the lid is in aluminum foil induction sealing gasket of bottled container, when the bottle through the electromagnetic wave sealing machine magnetic induction zone, covered in aluminum foil gasket will be induction identification, attached to the gasket on the metal aluminum instantly generate heat, melt the glue layer on the gasket to the bottle and incorporated into an organic whole, implementation firm product sealing effect.

Widely used in daily chemical, food, medicine, agrochemical industry and so on.

In the application of electromagnetic wave aluminum foil sealing packaging, we have integrated the following cases to answer common sealing problems from the Angle of sealing conditions:

Case 1

Case 2

Case 3

Case 4

Case 5

Case 6

Case 7

Problem: Leakage

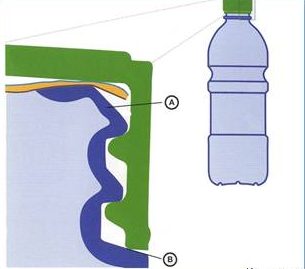

Defect:

1. The cover itself is designed without gasket.

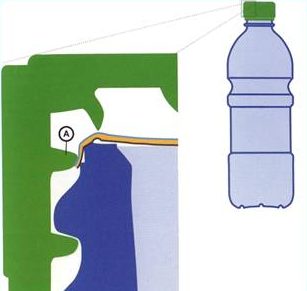

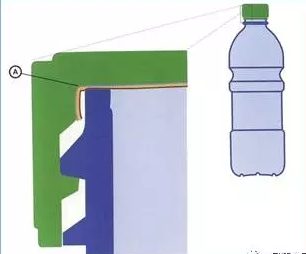

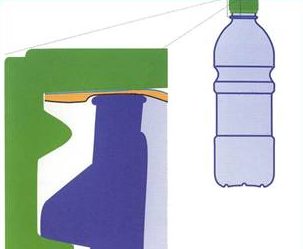

2. The cover is not designed so that the gasket can be stuck in position A smoothly, and the pressure of the gasket is uneven or insufficient.

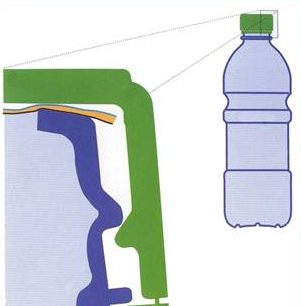

3. The gasket is stuck between the threads of the bottle and the cap, which may result in uneven bite of the threads when low torsion is applied.

Solutions/Suggestions:

1. Need to increase the torque.

2. Redesign the cover so that the gasket is stuck flat under position A to ensure that the gasket is not dropped.

To sum up the above cases, three key operating factors are required for a perfect sealing effect: Pressure — the correct mating of the cap and the bottle thread ensures the proper Pressure to the sealing gasket;Heat – Set the correct output power of the electromagnetic induction sealing machine to ensure that the sealing gasket gets the appropriate Heat;Time – Proper induction sealing procedures must ensure that the spacer passes through the sealing mouth at an accurate Time.