(1)PET material properties

PET raw material is a kind of milky white or light yellow highly crystalline polymer with a smooth and glossy surface. It has good creep resistance, fatigue resistance, abrasion resistance, good dimensional stability, small wear, and high hardness. It has the largest toughness in thermoplastic plastics: good electrical insulation performance, less affected by temperature, but poor corona resistance. Non-toxic, weather-resistant, chemical resistant, good stability, low water absorption, resistant to weak acid and organic solvents, but not resistant to hot water immersion, not resistant to alkali. Therefore, it is widely used in the packaging of the beauty and cosmetics industry.

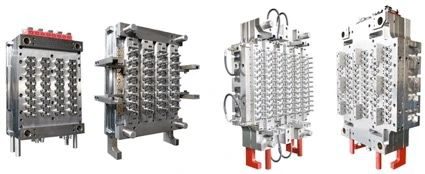

(2).Mold features

According to the project volume, the number of cavities of bottle embryo mold is from one to ninety-six. The template is P20 steel, which adopts the pre-hardening process. Core, cavity, and screw are made of s136h high strength, corrosion-resistant stainless steel. The formwork is finished by one-time processing, ensuring the concentricity of the forming hole and guide sleeve, and ensuring the compact structure of the mold.

1.Exclusive spiral cooling flume design for each single-core and cavity helps to shorten cycle time, improve production efficiency and save costs. The opening and closing plate adopt the bearing.

2. sliding-type so that the prefabricated parts have a reliable structure. It is a highly integrated sliding block, pushing plate, and ejection process. All sliding parts are inlaid with a self-lubricating copper alloy to ensure low friction efficiency and strong wear resistance.

3.Each cavity is self-locking to ensure high accuracy, reduce defects and facilitate disassembly.

4.Hot runner system: the heating temperature is uniform, which can prevent the White Defects of bottle embryo and improve the quality of plastic products.

(3)Key points of mold design

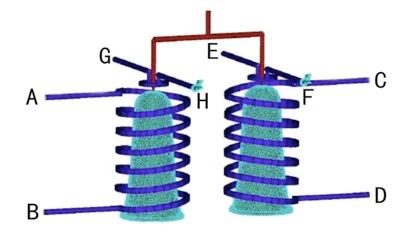

The cooling system is particularly important in mold design. The injection molding cycle of the product is shortened, the efficiency of the product is greatly improved, the size and surface effect of the product is more stable, and the quality of the product is improved. Key points of water transportation design:

1.Water transportation in front of bottle embryo mould is shown in the figure below:

Cooling water jacket is used to cool the gate of bottle embryo mold independently, and spiral cooling is used to cool the cavity to provide good mold temperature control.

The inlet and outlet of each cooling channel need to be connected separately, not in series, so as not to reduce the cooling series of the mold.

2.Water transportation of bottle embryo mold core is shown in the figure below:

The bottle embryo mold core adopts water delivery needle.

The cooling cycle is from inlet to top. The uniform cooling mode can make the product cool rapidly and improve the production efficiency and quality of the product.

(4).Bottle embryo injection molding

1.Pretreatment of raw plastics

Because of the fat group in pet macromolecules and certain hydrophilicity, the pellets are more sensitive to water at high temperatures. When the water content exceeds the limit, the molecular weight of the pet decreases during processing, and the products become colored and brittle. Therefore, the material must be dried before processing. The drying temperature is 150 â?for more than 4 hours, generally 170 â?for 3-4 hours. The air shooting method can be used to check whether the material is completely dry.

2.Precautions

The recovered material should not be too large, otherwise it is easy to “bridge” at the blanking place and affect the plasticization.

If the mold temperature is not controlled well or the material temperature is not controlled properly, it is easy to cause “white fog” and not transparent. Mold temperature is low and uniform, cooling speed is fast, less crystallization, the finished product is bright.

(5).Stretch blow molding

1.The two-step blowing method is used to heat the bottle embryo by heating the oven. The temperature of the bottle embryo is automatically adjusted by a manual setting. The cylinder embryo is heated by a lamp tube in the oven. The bottle embryo moves forward in the oven and rotates itself so that the bottle embryo is heated evenly.

2.The heat in the oven is controlled by the number of lamps, the overall temperature setting, the power of drying standard and the heating ratio of each section. The temperature adjustment should be combined with the effect of pre blowing bottle.

3.After heating the bottle embryo, it is transported to the blow mold by the transmission system of blow molding machine for blow molding process.

4.In the process of blow molding, the mold is kept cool. After blow molding and shaping, the transmission system drives to the packaging workbench to complete the packaging process.

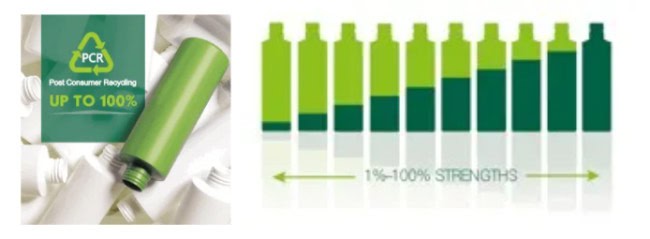

(6).Progress and status of application of ECO-friendly materials

1.Nowadays, more and more attention has been paid to environmental protection. R-PET (PCR) has been used in large quantities, from micro addition to 100% application. There is a perfect technical system for the detection and production of r-PET (PCR) materials.

2. Many batches of experiments and production have been carried out in the field of PLA corn starch. Due to the high cost, the current overall volume is not large.