Introduction to Polystyrene

Polystyrene is a type of thermoplastic that remains solid at room temperature, but starts to melt at 210 degrees Celsius. When it melts, polystyrene can be molded into different shapes and then solidified again by cooling, making it suitable for recycling. Polystyrene, in all its forms, has a degree of resistance to both acids and bases, rendering it dependable for daily use.

Polystyrene is a synthetic polymer known for its versatility and may be recognized as the material used in products like disposable cups, packaging peanuts, or insulation.

What Makes Polystyrene Unique?

- Composition: It is made from the monomer styrene, a substance derived from petroleum.

- Structure: In its polymer form, polystyrene consists of a long chain of hydrocarbon molecules with a phenyl group attached to every other carbon atom.

- Transparency: In its solid form, polystyrene is commonly transparent and rigid, making it suitable for applications where visibility of the contained item is important.

- Foamed Variety: It can also be foamed which leads to a lightweight material used in cushioning or insulation projects.

Given its property as a polymer, polystyrene is classified within the broad category of materials known as plastics. Its characteristics have made it a popular choice for a wide range of applications, from simple household items to complex uses in the electronics industry.

Chemical Composition and Structure

Polystyrene is a polymer made up of styrene units, showcasing a simple yet sturdy structure.

Styrene, a liquid hydrocarbon, is the monomer (or building block) of your polystyrene plastic. It’s an organic compound structured with a benzene ring—a hexagonal planar ring of six carbon atoms bonded with alternating double and single bonds—attached to a vinyl group. The vinyl group’s presence provides the ability for styrene to polymerize.

In layman’s terms, think of this monomer as a Lego piece that attaches to identical pieces to create a larger structure. The process is:

- Initiation: A catalyst triggers the styrene monomers to react.

- Propagation: The chain of monomers starts to grow as one styrene unit adds to another.

- Termination: This phase concludes the process, and you end up with the polymer chain.

Once you have polymerized styrene, it creates a solid material—polystyrene. Its structure is comprised of long chains where each second carbon atom connects to a phenyl group (part of the benzene ring). This structure gives polystyrene its characteristic properties such as clarity, stiffness, and ability to form both solid and foam products.

Physical Properties of Polystyrene

Transparency and Color

Polystyrene is naturally transparent, which allows light to pass through it without significant scattering. This transparency can be modified using colorants to produce polystyrene in virtually any color you desire, although the base material without additives is clear.

Thermal Properties

When it comes to heat, polystyrene has a relatively low melting point compared to other plastics. The material reaches its glass transition temperature at approximately 90°C to 100°C, transitioning from a hard, glassy material to a soft, rubbery state. However, this characteristic means that polystyrene isn’t ideal for high-temperature applications.

- Melting point: Typically around 240°C to 260°C

- Glass transition temperature: Approximately 90°C to 100°C

Mechanical Properties

Understanding polystyrene’s mechanical properties is essential. It’s known to be brittle and hard, which means it can crack under stress rather than deform. The tensile strength of polystyrene is generally moderate, allowing it to resist stretching forces to an extent. Its impact strength, however, can vary depending on the presence of additives or if it’s blended with other materials to create high-impact polystyrene (HIPS).

- Tensile strength: Ranges from 46 to 60 MPa

- Impact strength: Enhanced by adding rubber or other toughening agents

The molecular weight of the polymer chains in polystyrene affects its physical properties, with higher molecular weights typically leading to increased strength.

Types of Polystyrene

In this section, we will discuss the different forms of polystyrene.

General Purpose Polystyrene (GPPS)

General Purpose Polystyrene, or GPPS, is the most basic form of polystyrene. It’s transparent, brittle, and has a glassy texture, making it ideal for products where clarity is important, like laboratory ware or food packaging.

High Impact Polystyrene (HIPS)

For items that require more toughness, there’s High-Impact Polystyrene (HIPS). It is a blend of polystyrene and rubber, giving it a more flexible nature compared to GPPS. HIPS is less brittle and widely used for products that need to withstand impact, such as appliance housings and toy parts.

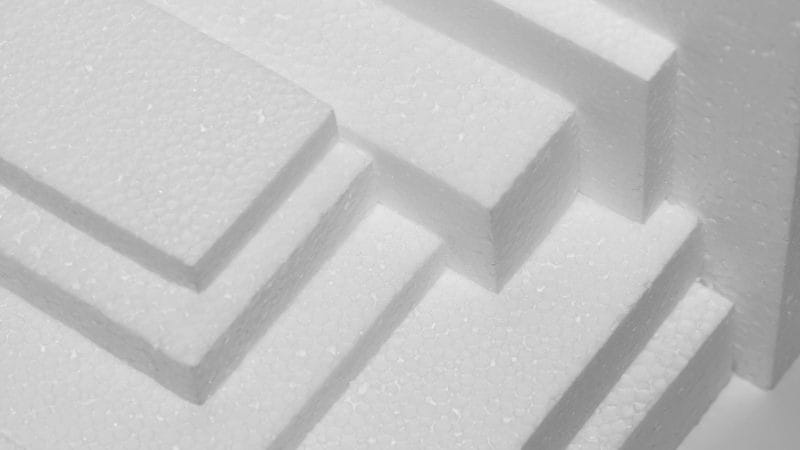

Expanded Polystyrene (EPS)

Expanded Polystyrene, commonly known as EPS, is a lightweight foam form of polystyrene. It’s composed of thousands of small beads fused together and is often found as protective packaging for electronics or as insulation material due to its excellent shock-absorbing properties.

Extruded Polystyrene (XPS)

Finally, there’s Extruded Polystyrene (XPS), which is similar to EPS but is made through a different process resulting in a smoother surface and closed-cell structure. This type is more moisture-resistant and has higher compressive strength, commonly used in building construction as an insulation board.

Production and Manufacturing of Polystyrene

Injection Molding

Injection molding allows you to turn polystyrene into a multitude of intricate shapes and sizes. In this process, polystyrene pellets are heated until molten and then injected into a metal mold. Once cooled, the plastic solidifies into the desired configuration. Injection molding is ideal for making a wide range of solid items such as disposable cutlery, cases for electronics, and toys.

Blowing Agents and Foam Production

When you need lightweight and insulated materials, polystyrene foam is the go-to. This is created using blowing agents that expand the polymer into a foam structure. A common example is the notorious Styrofoam™. During foam production, gases are introduced to the polystyrene, causing it to expand and solidify into lightweight materials. You’ll find this polystyrene foam used for packing materials, insulation, and disposable cups.

Extrusion

Extrusion is another key process in the production of polystyrene products. It involves pushing molten polystyrene through a die to create continuous shapes, like polystyrene sheets or polystyrene films. Typically, you’ll see extruded polystyrene as clear plastic sheets or as a part of multi-layered packaging. This method is adaptable, making it possible for you to produce a wide range of product thicknesses and sizes.

Applications of Polystyrene

Packaging Solutions

Polystyrene is used in packaging because of its lightweight, protective, and insulative properties.

- Foam Material: Commonly used in the form of expanded polystyrene, better known as Styrofoam, for egg cartons and protective packaging for electronics, keeping your products safe during transit.

- Food Packaging: Its ability to keep food fresh makes it ideal for creating containers and cups for various food items.

Consumer Goods

Polystyrene’s application in consumer goods touches your daily life in numerous ways.

- Toys: This plastic’s durability is perfect for manufacturing a variety of toys, ensuring they are robust and long-lasting.

- Housewares: Polystyrene also finds use in items like non-disposable cutlery, plates, and CD/DVD cases due to its rigid structure.

Construction and Insulation

In construction, polystyrene plays a significant role, owing to its insulation properties.

- Insulation: Its excellent thermal resistance is why you’ll find polystyrene as insulation material for walls and roofs, helping maintain temperature control within buildings.

Medical and Laboratory

Polystyrene’s clear and sterile nature is perfect for a range of medical applications.

- Medical Equipment: It is often used to make sterile medical test tubes, Petri dishes, and other lab ware that require precision and cleanliness.

Environmental Impact and Recycling

Polystyrene, often found in disposable containers and packaging material, presents significant challenges in waste management and recycling efforts. Your awareness of its environmental footprint and recyclability is vital.

Recyclability of Polystyrene

While polystyrene, including expanded polystyrene (EPS), is used widely due to its versatility, its presence in the recycling stream is limited. Your traditional curbside recycling program might not accept it due to sorting and contamination issues. Recycling polystyrene often involves a process known as densification, where the volume is reduced for transportation to specialized facilities. These processes require specific equipment, and the number of facilities equipped to handle polystyrene recycling is less than those for more commonly recycled materials like PET or HDPE containers. In 2018, PET bottles and jars saw a recycling rate of 29.1%, while HDPE natural bottles were recycled at a rate of 29.3%. Polystyrene, however, lags significantly behind these materials.

- Recycling Rates:

- PET bottles and jars: 29.1%

- HDPE natural bottles: 29.3%

- Polystyrene: Significantly lower

Biodegradability and Alternatives

Polystyrene is not biodegradable, leading to its accumulation in landfills and the natural environment, including oceans. As you consider its environmental impact, be mindful that it can take hundreds of years to break down, contributing to persistent waste issues. Researchers have been working on green, low-energy processes to break down polystyrene, with hopes to mitigate its environmental footprint. Furthermore, there are more eco-friendly alternatives available, focusing on renewable materials and increased biodegradability, like plant-based plastics that degrade more readily in natural environments. When you’re choosing packaging materials or disposable containers, selecting products made with these alternatives can help reduce your environmental footprint.

- Alternatives to Polystyrene:

- Plant-based plastics

- Compostable materials

- Recyclable paper products

Health and Safety Considerations

When dealing with polystyrene products, you must be conscious of the health and safety implications related to the materials used and the regulatory frameworks in place.

Toxicity and Exposure

You should be aware that polystyrene is made from styrene, which can be toxic if you’re exposed to it at high levels. Typically, exposure might occur through inhalation or skin contact. If you work in manufacturing or environments where polystyrene is produced or processed, you could be at risk for mucous membrane irritation, eye irritation, and gastrointestinal effects from acute (short-term) exposure to styrene.

For your safety when using polystyrene in applications such as food containers, it’s important to understand that small amounts of substances can leach into the food, particularly with hot contents or when heated. However, the degree to which these substances can leach is generally low and considered safe under normal conditions of use.

Regulations and Standards

There are established regulations and standards that ensure the safe use of polystyrene, especially when it comes in contact with food or is used in medical settings. To protect your health:

- FDA Regulations: The U.S. Food and Drug Administration (FDA) regulates the safety of polystyrene in food contact applications. Food containers made from polystyrene must meet strict standards for safety and the potential for toxic substances to leach into food.

- OSHA Standards: For those who work with styrene in an industrial capacity, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits to styrene. Always consult the latest standards to guarantee your working conditions meet legal safety requirements.

It’s crucial for you to stay informed about the safety data sheets provided by manufacturers for materials like polystyrene, which detail proper handling procedures and protective measures to take.

By adhering to these guidelines and standards, you can manage the risks associated with polystyrene use and ensure that your exposure to potential toxins is minimized across various applications.

Market Trends and Manufacturers

As you explore the polystyrene market, you’ll notice it’s characterized by continuous growth and innovation. Companies leading the production of polystyrene are pushing the boundaries, ensuring that it remains a vital material in various industries. Here’s a closer look at the key players and the cutting-edge advancements they’re making.

Leading Companies

- Dow: This major player, previously known as Dow Chemical Company, has a significant footprint in the polymer industry. Dow offers a variety of polystyrene products that cater to a diverse set of applications.

- BASF: Not far behind is BASF, a company known for its commitment to quality and sustainability. BASF’s styrol-based polymers are essential in creating high-performance polystyrene.

These manufacturers not only dominate the market but also invest in research and develop to maintain a competitive edge.

Innovations in Polystyrene

Polystyrene manufacturers are not just resting on their laurels; they’re constantly innovating. Here’s what you should be on the lookout for:

- Recyclable Solutions: With the increasing emphasis on environmental sustainability, companies are pioneering the creation of recyclable polystyrene materials.

- Enhanced Properties: Through innovative research, companies are developing polystyrene with improved qualities—like increased impact resistance and insulation properties—to meet changing market demands.

The push for innovation ensures that polystyrene remains a versatile and invaluable material across various sectors.

Frequently Asked Questions

How is polystyrene produced?

Polystyrene is manufactured by polymerizing styrene, a substance derived from petroleum. This chemical process involves the linking of styrene monomers to form long polymer chains, resulting in the versatile plastic known as polystyrene.

What are the common uses of polystyrene in everyday products?

You’ll find polystyrene in various forms such as food packaging, disposable cups and plates, insulation materials, and even in consumer electronics casings due to its lightweight and moldable nature.

Can polystyrene be easily recycled?

Recycling polystyrene can be challenging due to the collection and cleaning processes. However, some recycling programs and initiatives accept it, often focusing on specific forms like expanded polystyrene foam.

What are the properties that distinguish polystyrene from other plastics?

Polystyrene stands out for its clarity, rigidity, and ability to be molded into different shapes when heated. It’s also resistant to moisture, making it suitable for food packaging.

Is polystyrene considered environmentally friendly?

Polystyrene is not typically considered environmentally friendly because it does not biodegrade easily and can persist in the environment for a long time. Efforts to improve its sustainability include recycling and developing biodegradable alternatives.

How does the structure of polystyrene relate to its physical characteristics?

The structure of polystyrene, with its long polymer chains, contributes to its strength and durability. Its ability to be either rigid or foamed allows for versatility across various applications, from solid products to insulation materials.