Plastic Cap

"*" indicates required fields

You can revamp your packaging style with a beautiful cosmetic plastic cap. They are widely used for cosmetic products, and the manufacturing style is injection mode.

Functionality

The cosmetic plastic cap attracts customers with its stylish and alluring designs. It is well designed with an ergonomic opening that makes opening your bottles effortless.

Different Specification

The airtight caps effectively package cosmetic products such as shampoos, conditioners, moisturizers, toners, cleaners, etc. The cap type includes a screw cap, disc-top cap, and flip cap.

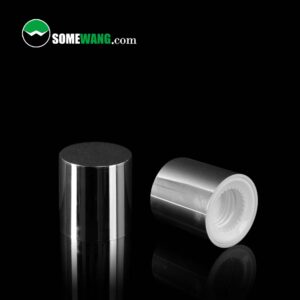

Screw Cap Surface handling: Uses alumite, UV Plating, and water transfer printing.

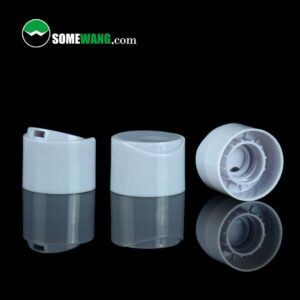

Disc-top cap Surface handling: Uses alumite and water transfer printing. It comes in the following neck sizes- 18/410, 20/410, 24/410, 28/410.

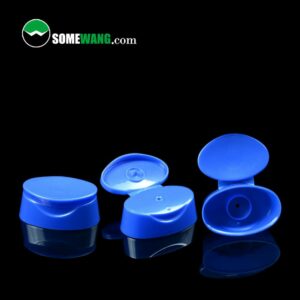

Flip cap Surface Handling: Uses UV plating and water transfer printing. Comes in the following neck sizes- 15/410, 18/410, 20/410, 24/410, 28/410.

Safe to Use

The materials of cosmetic plastic bottles are made from PP, PE, PS, and ABS. These materials are safe to use and environmentally friendly.

It features a specialized design that ensures child safety and storage benefits. The materials used for production have better design and toughness.

Various Uses

The cosmetic industries rely heavily on plastic caps to package a wide range of products. The packaging comes in various custom and standard caps, including screw, disc top, and flip caps.

They also come in different colors, sizes, and shapes. The cosmetic plastic caps are lightweight, making them easy and convenient to carry around.

High-Quality Materials

The high-density polyethylene has excellent resistance to chemicals and dampness. Similarly, the PP material has the same attributes to greater resistance to heat and poor resistance to cold. PS ( General Purpose Polystyrene) is tasteless, odorless, and more recyclable.

ABS (Acrylonitrile-Butadiene-Styrene) is more resistant to crushing, chemicals, and oils. It is also easily manufactured to specification.

Customized Design

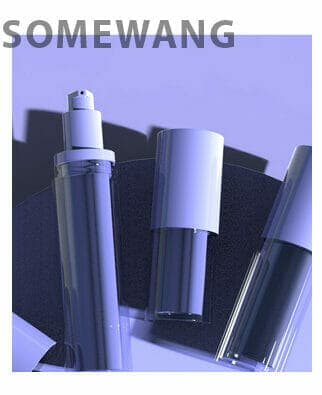

The cosmetic plastic cap can be custom-made to suit your preferred color, capacity, and style with a professional design team.

Different industries use different designs, sizes, and shapes of plastic caps. Your plastic cap can be produced using a sketch provided. This process can also include 3D images, technical drawings, and initial production samples.

Cost-Effective

The cosmetic plastic cap offers the user an opportunity to save costs. The production is done in large volume, making it affordable to both small and large businesses. More so, the plastic cap is designed to minimize waste, ultimately saving costs.

Aesthetically Pleasing

It can be made into magnetic white, transparent, and colored. The materials have high barrier properties, lightweight. The ergonomic, stylish, and modern design makes it eye-catching to the users.

Large Production

Buying cosmetic plastic caps in large quantities is the perfect solution for consumers sold through large retailers to the end-users. These products include lotions, liquid soap, shampoo, and conditioner.

The cosmetic plastic caps are packed with solid aesthetic appeal that provides a strong personality and improves the final product’s sales while ensuring maximum functionality and customer satisfaction.